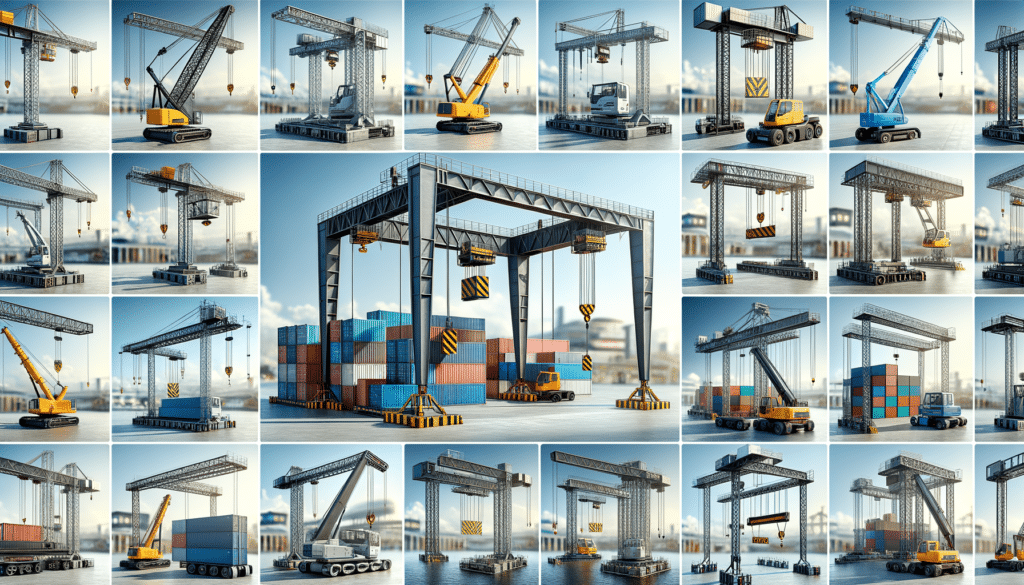

Understanding Affordable Gantry Cranes

When it comes to lifting heavy loads without breaking the bank, affordable gantry cranes are an attractive option for many businesses. These cranes offer a cost-effective solution for handling materials in warehouses, workshops, and even on construction sites. The key to finding an affordable gantry crane is to balance cost with functionality, ensuring that the crane meets your specific lifting requirements without unnecessary features that drive up the price.

Affordable gantry cranes typically come in various configurations, including fixed and adjustable models. Fixed models offer a stable and reliable option for repetitive tasks, while adjustable models provide flexibility for different load sizes and heights. Additionally, the material used in construction, such as steel or aluminum, can significantly impact the price and durability of the crane.

When selecting an affordable gantry crane, consider the following factors:

- Lifting capacity: Ensure the crane can handle the maximum weight you need to lift.

- Height and span: Choose a crane that fits your workspace dimensions.

- Portability: Determine if you need a crane that can be easily moved around your work area.

- Assembly and maintenance: Look for models that are easy to assemble and maintain, reducing long-term costs.

By carefully assessing these factors, you can find an affordable gantry crane that meets your needs without compromising on quality or safety.

The Versatility of Portable Gantry Cranes

Portable gantry cranes are a versatile and practical choice for businesses that require flexibility in their lifting operations. These cranes are designed to be easily moved and set up in different locations, making them ideal for workshops, repair facilities, and temporary job sites. Their portability allows users to adapt to changing work environments without the need for permanent installations.

One of the main advantages of portable gantry cranes is their ability to be quickly assembled and disassembled. This feature is particularly beneficial for businesses that need to transport the crane between different sites. Additionally, many portable gantry cranes come with adjustable height and span options, allowing for customization based on the specific task at hand.

When choosing a portable gantry crane, consider the following aspects:

- Weight capacity: Ensure the crane can handle the heaviest load you expect to lift.

- Ease of mobility: Look for cranes with wheels or casters for smooth movement.

- Material: Aluminum cranes offer lightweight portability, while steel provides durability.

- Setup time: Opt for cranes that can be quickly assembled to minimize downtime.

Portable gantry cranes offer a practical solution for businesses that need a flexible and mobile lifting option, providing the ability to efficiently move and handle materials across various locations.

Exploring the Role of Jib in Cranes

The jib is a critical component in many types of cranes, including gantry cranes, and plays a significant role in their operation. Essentially, the jib is the horizontal arm that extends from the crane’s main structure, allowing for the lifting and movement of loads. This component is pivotal in determining the crane’s reach and flexibility in handling materials.

Jib cranes are particularly valued for their ability to lift loads in confined spaces where traditional cranes may not fit. They are often used in workshops, manufacturing facilities, and warehouses where precise movement and placement of materials are required.

Key considerations when evaluating the jib in a crane include:

- Length and reach: The length of the jib determines how far the crane can extend to pick up and place loads.

- Rotation: Some jibs offer full 360-degree rotation, providing greater flexibility in movement.

- Load capacity: Ensure the jib can support the weight of the materials being lifted.

- Material: Choose between steel or aluminum jibs based on the balance between weight and strength needed.

Understanding the role and capabilities of the jib in a crane is essential for selecting the right equipment for your lifting needs. A well-chosen jib can enhance the efficiency and safety of material handling operations.