What to Know About Hydraulic Press Machines in Workshop and Industrial Settings

Introduction to Hydraulic Press Machines

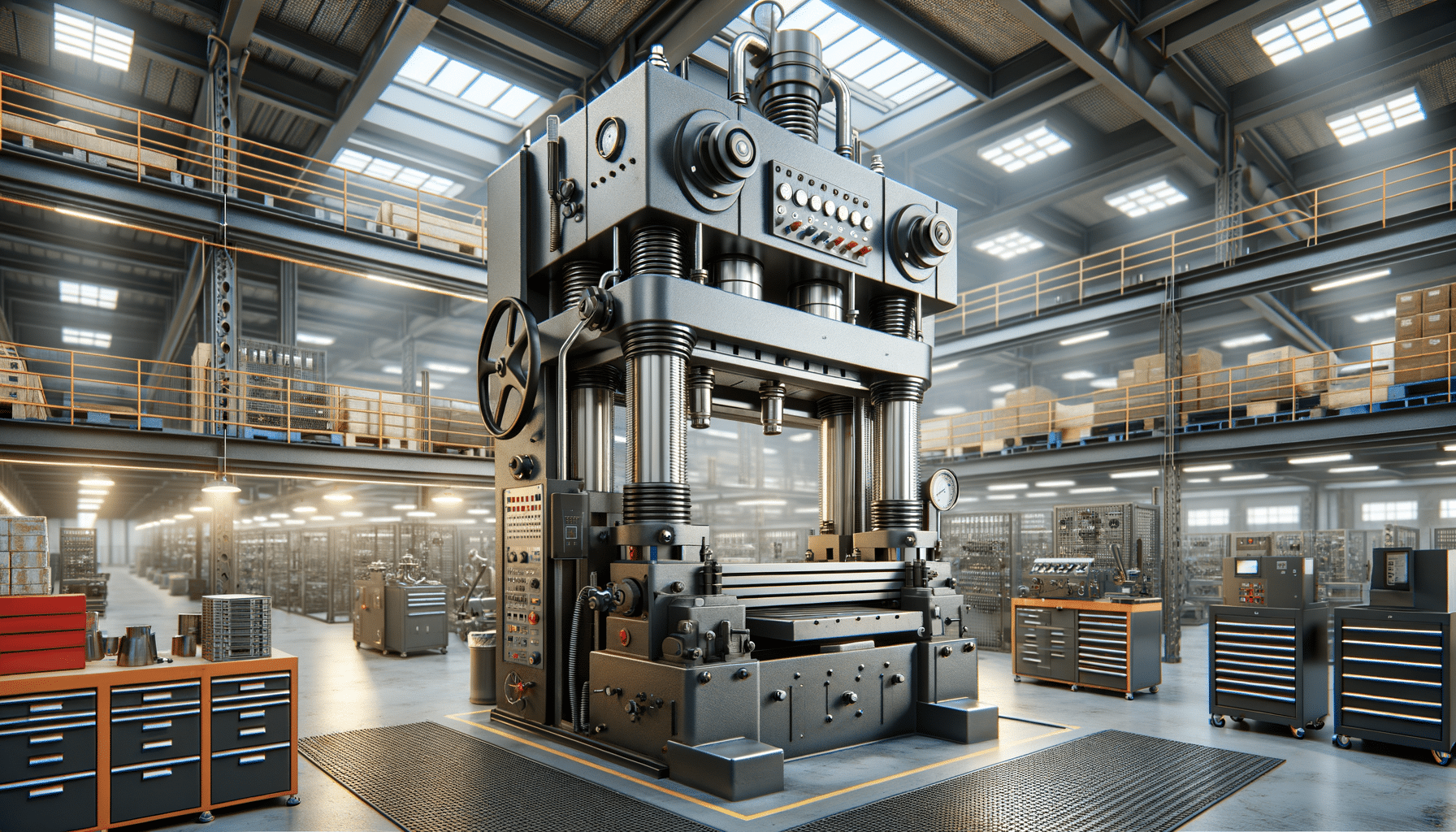

Hydraulic press machines are a pivotal component in both workshop and industrial settings. These machines utilize hydraulic cylinders to generate a compressive force, making them indispensable for tasks requiring the shaping or compressing of materials. The relevance of hydraulic press machines extends across various industries, from automotive to aerospace, due to their ability to handle a wide range of applications with precision and efficiency.

Understanding the different aspects of hydraulic press machines, including their types, capabilities, and operational methodologies, is crucial for businesses and individuals looking to invest in this technology. The following sections explore these aspects in detail, providing valuable insights into their functionality and benefits.

Understanding Hydraulic Press Machines

Hydraulic press machines operate on the principle of Pascal’s law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle allows hydraulic presses to exert significant force with relatively small input efforts. The primary components of a hydraulic press include a hydraulic cylinder, a pump, and a series of valves and pipes that control the flow of hydraulic fluid.

These machines are categorized based on their design and functionality, with common types including:

- H-frame presses: Known for their versatility and ability to apply uniform force over large areas.

- C-frame presses: Compact and ideal for operations with limited space.

- Four-column presses: Provide balanced pressure distribution and are suitable for heavy-duty applications.

The choice of a hydraulic press machine depends on the specific requirements of the task at hand, including the material type, required pressure, and operational environment.

Exploring the Shop Press

A shop press is a type of hydraulic press machine commonly found in workshops and small-scale manufacturing units. These presses are designed for tasks such as bending, straightening, and pressing components. Shop presses are valued for their compact size, affordability, and ease of use, making them a popular choice for automotive repair shops and metalworking facilities.

Shop presses typically feature an H-frame or C-frame design, allowing users to perform a variety of operations with precision. They are equipped with a pressure gauge for monitoring the force applied, ensuring consistent results. The versatility of shop presses is enhanced by the availability of various attachments and accessories, enabling users to customize the machine for specific tasks.

Before purchasing a shop press, it is essential to consider factors such as the maximum pressure capacity, frame design, and available workspace. These considerations ensure that the chosen machine meets the operational demands and delivers optimal performance.

The Role of Industrial Press Machines

Industrial press machines are robust and powerful tools designed for large-scale manufacturing and heavy-duty applications. These machines are capable of applying immense pressure, making them suitable for tasks such as forging, stamping, and molding in industries like automotive, aerospace, and construction.

Industrial press machines are characterized by their sturdy construction and advanced features, including automated controls and programmable settings. These features enhance productivity and precision, allowing manufacturers to produce high-quality components with minimal waste. The integration of technology such as sensors and real-time monitoring systems further optimizes the performance of industrial press machines.

Investing in an industrial press machine requires careful consideration of factors such as production volume, material type, and specific application requirements. Businesses must also assess the long-term benefits, including increased efficiency and reduced labor costs, to ensure a successful investment.

Conclusion: Choosing the Right Press Machine

When selecting a hydraulic press machine, whether for a workshop or industrial setting, it is crucial to evaluate the specific needs and operational goals. Understanding the differences between shop presses and industrial presses, along with their respective capabilities, ensures that the chosen machine aligns with the intended applications.

Hydraulic press machines offer significant advantages in terms of precision, efficiency, and versatility. By investing in the right press machine, businesses can enhance their production processes, improve product quality, and achieve greater operational success. As technology continues to evolve, the future of hydraulic press machines promises even more innovative solutions for diverse industrial challenges.