The Benefits of Using Carbon Steel in Construction

Introduction to Carbon Steel Coils

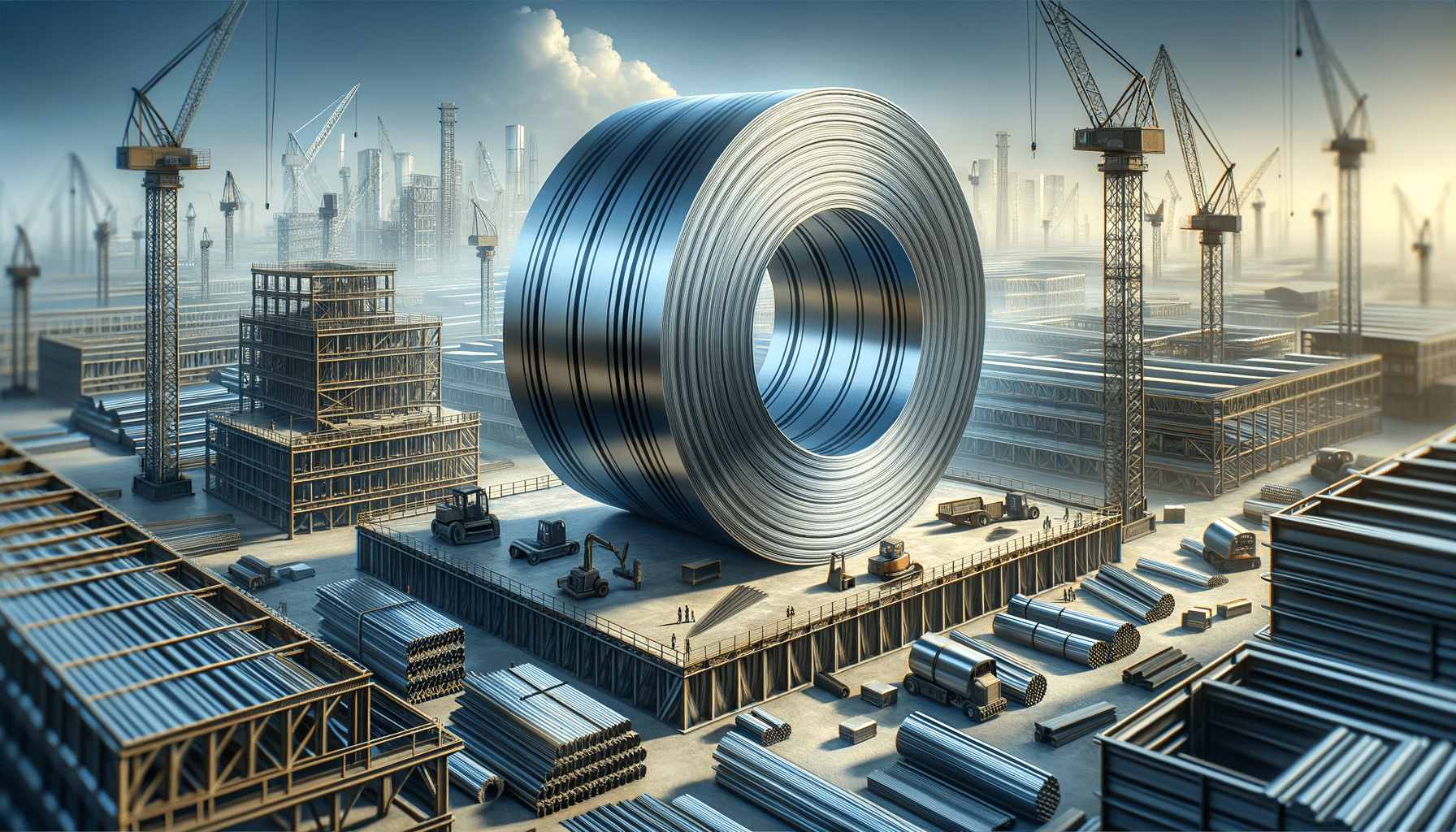

Carbon steel coils are a fundamental component in the construction and manufacturing industries, offering a range of benefits that make them indispensable. These coils are produced by rolling steel into a coil shape, which can then be used in various applications. The versatility and strength of carbon steel make it a preferred choice for many engineers and builders. Its ability to withstand extreme temperatures and resist shocks contributes to its widespread use in creating durable structures.

Carbon steel coils are particularly valued for their durability and recyclability. As industries increasingly focus on sustainable practices, the recyclable nature of carbon steel becomes a significant advantage. Additionally, the affordability of carbon steel makes it accessible for a wide range of projects, from large-scale constructions to smaller, more intricate designs.

Exploring Carbon Steel Coil Sizes

The size of carbon steel coils can vary greatly, depending on the requirements of the project. Standard sizes are typically used in construction, but custom sizes can also be manufactured to meet specific needs. The thickness of the coil is a crucial factor that determines its application. Thicker coils are often used in heavy-duty construction, while thinner ones are suitable for more delicate work.

Understanding the different sizes available can help project managers and engineers select the right coil for their specific application. Commonly, carbon steel coils are categorized by their width, thickness, and weight, allowing for precise specifications. This flexibility in sizing ensures that carbon steel coils can be adapted to a wide variety of uses, from structural components to intricate machinery parts.

- Width: Varies from narrow strips to wide sheets.

- Thickness: Ranges from thin sheets to thick plates.

- Weight: Can be adjusted according to the length and thickness of the coil.

Understanding High Carbon Steel

High carbon steel is a type of carbon steel that contains a higher carbon content, typically more than 0.6%. This increased carbon content gives the steel enhanced hardness and strength, making it ideal for applications that require wear resistance and durability. High carbon steel is commonly used in cutting tools, springs, and high-strength wires.

One of the key advantages of high carbon steel is its ability to retain a sharp edge, which is why it is often used in knives and blades. However, this increased hardness also makes it more brittle, which can be a disadvantage in applications where flexibility is required. Engineers must carefully consider the balance between hardness and ductility when selecting high carbon steel for specific projects.

In summary, high carbon steel offers exceptional quality and strength, making it suitable for specialized applications where durability is paramount. Its use in the construction industry is limited to specific areas where its properties are most beneficial.

Applications of Carbon Steel Coils in Construction

Carbon steel coils are extensively used in the construction industry due to their versatility and strength. They are often employed in the creation of structural components, such as beams and columns, which require robust materials to support buildings and infrastructure. The ability of carbon steel coils to withstand high stress and extreme temperatures makes them ideal for use in challenging environments.

In addition to structural applications, carbon steel coils are also used in the manufacturing of pipelines, bridges, and various types of machinery. Their adaptability allows them to be shaped and formed into a wide range of products, ensuring their continued relevance in modern construction practices.

- Structural Components: Beams, columns, and reinforcing bars.

- Infrastructure: Bridges, pipelines, and transport systems.

- Machinery: Parts and components for industrial machinery.

Conclusion: The Future of Carbon Steel in Construction

As the construction industry continues to evolve, the demand for materials that offer both strength and sustainability is increasing. Carbon steel coils, with their exceptional properties, are well-positioned to meet these demands. Their durability, affordability, and recyclability make them a preferred choice for various applications in construction.

Looking forward, innovations in carbon steel production and processing are likely to enhance its properties further, making it even more versatile and efficient. As industries continue to prioritize environmentally friendly practices, the recyclability of carbon steel will become an even more significant advantage. In conclusion, carbon steel coils will remain a cornerstone of construction materials, supporting the development of infrastructure and the advancement of modern engineering.