Fiberglass Grating: The Durable, Lightweight Solution for Industrial and Commercial Applications

Fiberglass Grating Installation

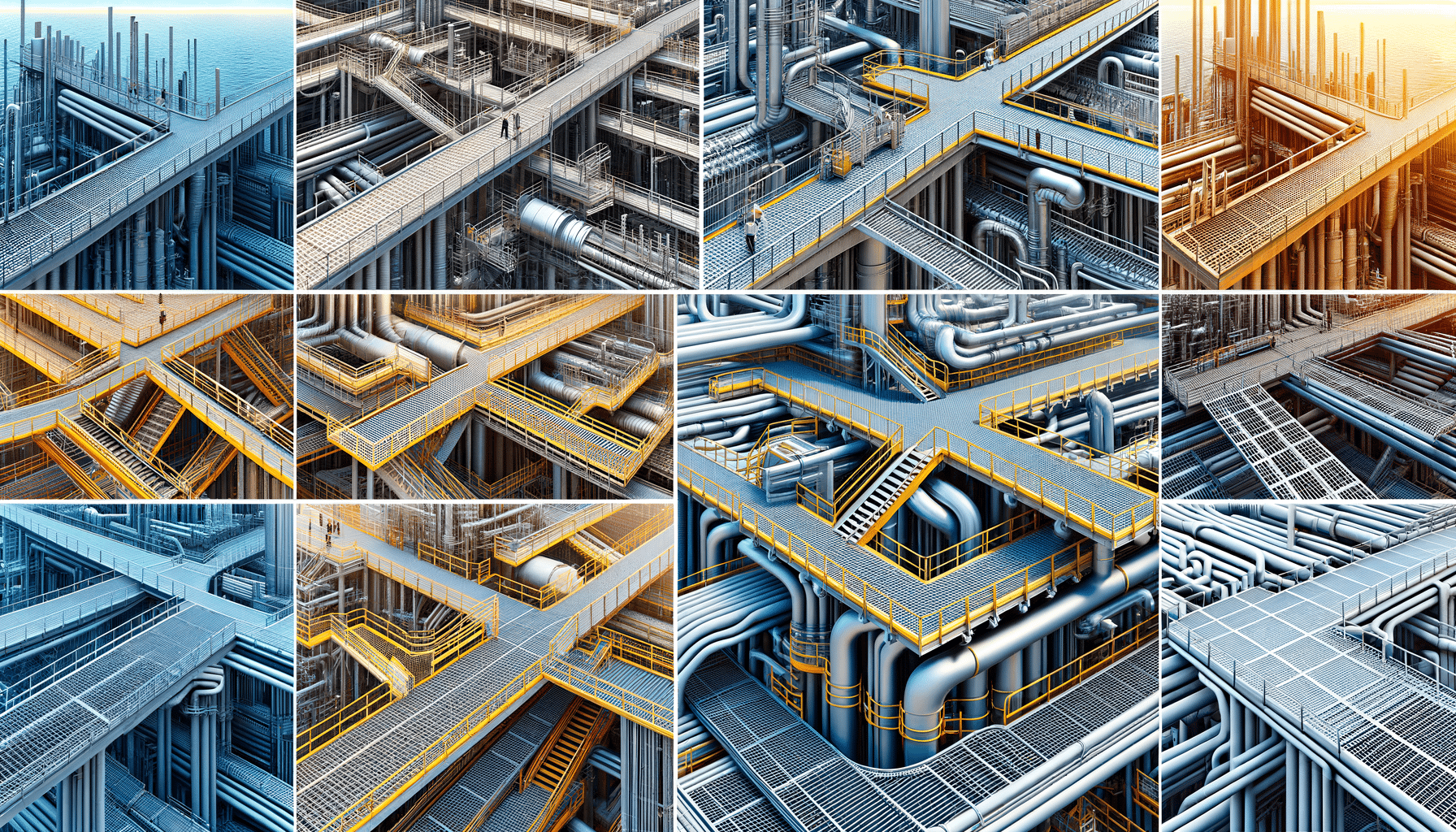

Installing fiberglass grating is a straightforward process, yet it requires precision to ensure safety and effectiveness. First, it’s essential to prepare the installation site, ensuring it’s clean, level, and free of debris. Fiberglass grating can be cut on-site using standard tools such as circular saws with diamond-tipped blades. This flexibility allows for customization to fit unique space requirements. When placing the grating, ensure it is properly supported and secured to prevent movement under load. Fasteners specifically designed for fiberglass grating are recommended, as they provide the necessary grip without causing damage to the material.

Once installed, fiberglass grating offers a durable and safe walking surface. It is crucial to regularly inspect the installation to ensure that all fasteners remain tight and the grating is not experiencing undue stress. Proper installation not only enhances safety but also extends the lifespan of the grating, making it a cost-effective choice for industrial and commercial environments.

FRP Grating Benefits

Fiberglass Reinforced Plastic (FRP) grating offers numerous advantages over traditional materials like steel or aluminum. One of the primary benefits is its corrosion resistance. FRP grating does not rust or corrode, making it ideal for environments exposed to moisture, chemicals, or salty air. This characteristic significantly reduces maintenance needs and extends the lifespan of the grating.

Additionally, FRP grating is lightweight, which simplifies handling and installation. This feature can lead to reduced labor costs and easier transportation. Despite its light weight, FRP grating is exceptionally strong, often outperforming metal grating in terms of strength-to-weight ratio. It also provides excellent slip resistance, which enhances safety in wet or oily conditions.

FRP grating is non-conductive, making it safer in environments where electrical conductivity is a concern. Its versatility and adaptability make it suitable for a wide range of applications, from industrial platforms to pedestrian walkways.

Types of Fiberglass Grating

Fiberglass grating comes in various types, tailored to meet different application needs. The two primary types are molded and pultruded grating. Molded grating is made by pouring resin and fiberglass into a mold, resulting in a grid that is strong and resilient. It’s particularly useful in applications where bi-directional strength is required, such as in platforms and walkways.

Pultruded grating, on the other hand, is manufactured by pulling resin-coated fiberglass through a heated die. This process creates a grating with high unidirectional strength, making it suitable for applications that require longer spans or higher load capacities. Pultruded grating is often used in industrial settings where heavy machinery or equipment is present.

Both types of fiberglass grating offer unique benefits and can be tailored with different surface textures and colors to suit specific aesthetic and functional requirements. Understanding the differences between molded and pultruded grating helps in selecting the right type for your specific needs.