Fiberglass Grating: The Durable, Lightweight Solution for Industrial and Commercial Applications

Fiberglass Grating Installation

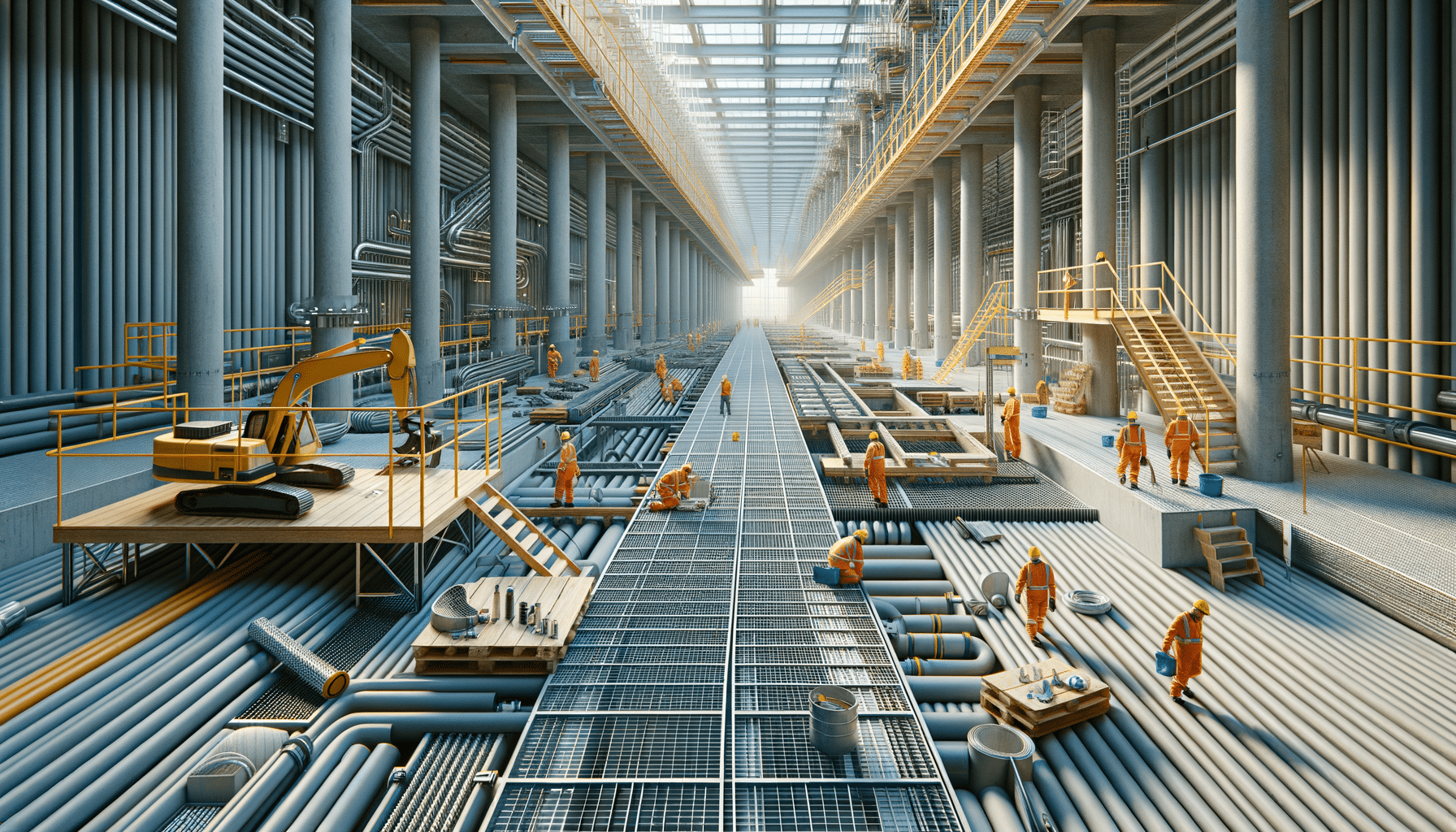

Fiberglass grating installation is a straightforward process that offers a host of benefits for industrial and commercial settings. The lightweight nature of fiberglass makes it easy to handle and position, reducing the need for heavy machinery and extensive labor. This ease of installation not only saves time but also cuts down on costs. When installing fiberglass grating, it’s essential to prepare the surface properly. Ensure that the area is clean and free from debris, as this will help the grating to sit evenly and securely.

Once the site is prepared, the grating panels can be laid out according to the design plan. It is crucial to follow the manufacturer’s specifications regarding spacing and support to maintain structural integrity. Fasteners specifically designed for fiberglass should be used to secure the grating, as they will help prevent damage and ensure longevity. Proper installation also involves checking for alignment and making necessary adjustments to avoid any potential safety hazards.

For those new to fiberglass grating installation, consulting with a professional or referring to detailed guides can be beneficial. The process is generally user-friendly, but attention to detail is paramount to ensure the grating serves its purpose effectively. With proper installation, fiberglass grating can provide a durable, reliable surface for years to come.

FRP Grating Benefits

Fiber Reinforced Plastic (FRP) grating offers numerous advantages that make it an attractive option for various applications. One of the most significant benefits is its corrosion resistance. Unlike metal grating, FRP does not rust or corrode when exposed to harsh chemicals or moisture, making it ideal for environments such as chemical plants, wastewater treatment facilities, and coastal areas. This resistance extends the lifespan of the grating, reducing the need for frequent replacements and maintenance.

Another notable benefit of FRP grating is its lightweight nature. This characteristic simplifies transportation and installation, as it can be easily maneuvered without the need for specialized equipment. Despite its light weight, FRP grating is remarkably strong, capable of supporting substantial loads without compromising safety. This strength-to-weight ratio is one of the reasons FRP is favored in industries where both durability and ease of use are critical.

FRP grating is also non-conductive and fire-resistant, enhancing safety in environments where electrical hazards or fire risks are present. The material’s non-slip surface provides additional safety by reducing the risk of slips and falls, which is particularly important in wet or oily conditions. With these benefits, FRP grating stands out as a versatile and reliable choice for a wide range of applications.

Types of Fiberglass Grating

There are several types of fiberglass grating available, each designed to meet specific needs and applications. The most common types include molded and pultruded grating. Molded fiberglass grating is created by laying glass fibers in a mold and saturating them with resin. This process results in a one-piece construction that is strong and durable. Molded grating is ideal for applications requiring bi-directional strength and is often used in environments where chemical resistance is crucial.

Pultruded fiberglass grating, on the other hand, is made by pulling glass fibers through a resin bath and then through a heated die. This method produces a grating with a high strength-to-weight ratio and is particularly suited for applications that require high load-bearing capacity. Pultruded grating is typically used in industrial settings where long spans are necessary, as it provides excellent stiffness and strength.

In addition to molded and pultruded grating, there are specialized types such as covered grating, which features a solid top surface. This type is used when a smooth, solid walking surface is needed, providing additional safety and comfort. Each type of fiberglass grating offers unique benefits, allowing for tailored solutions that address specific challenges and requirements in various environments.