Introduction to Box Making Machines

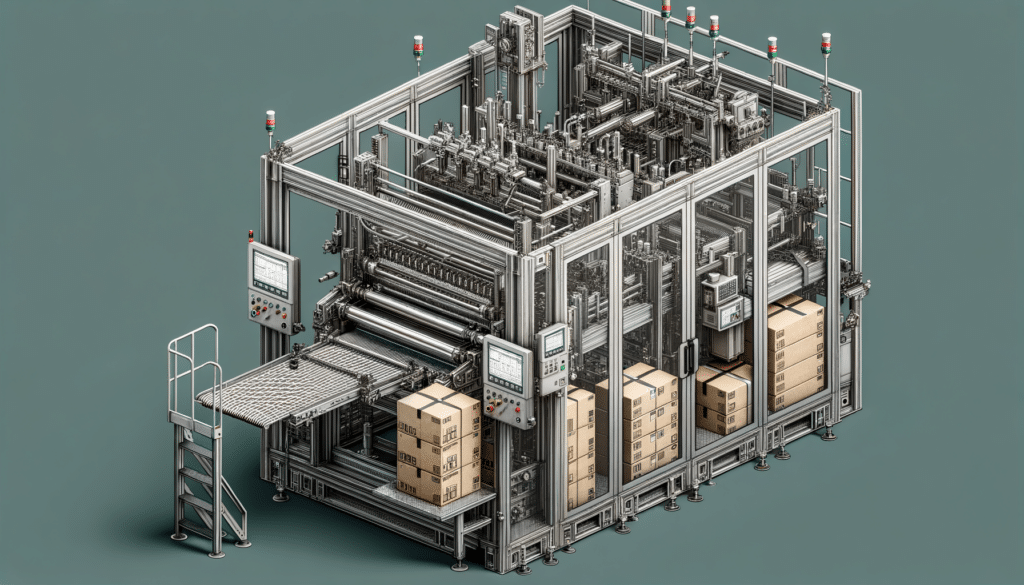

In today’s fast-paced industrial landscape, efficiency is paramount, and packaging plays a crucial role in the supply chain. As businesses strive to optimize operations, the demand for advanced packaging solutions like box making machines has surged. These machines are designed to streamline the packaging process, offering a seamless solution for creating boxes of various sizes and shapes. With the ability to produce custom boxes on demand, these machines are an invaluable asset for businesses looking to enhance their packaging capabilities.

Box making machines are versatile, catering to a wide range of industries, including e-commerce, manufacturing, and logistics. Their adaptability makes them suitable for producing boxes for electronics, food products, and more. By automating the box creation process, companies can reduce labor costs, minimize waste, and improve overall productivity. As we delve deeper into the realm of packaging technology, we’ll explore the different types of box making machines and their applications in various sectors.

Understanding Automatic Carton Forming Equipment

Automatic carton forming equipment represents a significant leap forward in packaging technology. These machines are engineered to automatically shape, fold, and secure cartons, making them an essential component in high-volume production environments. The automation of carton forming not only speeds up the packaging process but also ensures consistency and precision in every box produced.

One of the key advantages of automatic carton forming equipment is its ability to handle diverse carton designs and sizes. Whether it’s a simple rectangular box or a complex, multi-sided carton, these machines can be programmed to meet specific packaging requirements. This flexibility is particularly beneficial for businesses that need to adapt quickly to changing market demands or product lines.

Moreover, automatic carton forming equipment is equipped with advanced features such as touch-screen interfaces, programmable logic controllers (PLCs), and sensors that enhance operational efficiency. These machines can integrate seamlessly with other packaging systems, creating a cohesive and streamlined production line. As a result, businesses can achieve higher throughput rates while maintaining quality and reducing the risk of errors.

Choosing the Right Industrial Box Machine Supplier

Selecting an industrial box machine supplier is a critical decision that can impact a company’s packaging operations. With numerous suppliers in the market, it’s essential to evaluate them based on several criteria to ensure the best fit for your business needs. The right supplier should offer machines that align with your production goals, budget, and technical requirements.

When assessing potential suppliers, consider their reputation and experience in the industry. A supplier with a proven track record of delivering high-quality machinery and excellent customer service is likely to be a reliable partner. Additionally, inquire about the range of machines they offer, including any customization options that might be available to tailor the equipment to your specific needs.

Another important factor is the level of support and maintenance services provided by the supplier. A reputable supplier should offer comprehensive after-sales support, including training, technical assistance, and access to spare parts. This ensures that your equipment remains in optimal condition and minimizes downtime in the event of technical issues. By carefully evaluating these aspects, businesses can select a supplier that not only meets their immediate needs but also supports their long-term growth and success.

Innovations in Box Making Technology

The packaging industry is continuously evolving, with innovations in box making technology leading the charge. Recent advancements have focused on enhancing the efficiency, sustainability, and versatility of box making machines. These innovations are driven by the need to reduce environmental impact and meet the growing demand for eco-friendly packaging solutions.

One of the notable trends is the integration of smart technology into box making machines. This includes the use of IoT (Internet of Things) devices and AI (Artificial Intelligence) to optimize machine performance. These technologies enable real-time monitoring and predictive maintenance, allowing businesses to address potential issues before they escalate into costly downtime.

Additionally, sustainable materials and processes are being incorporated into box making technology. Machines are now capable of using recycled materials and minimizing waste during production. This shift towards sustainability not only benefits the environment but also aligns with consumer preferences for eco-friendly products. As these innovations continue to shape the industry, businesses can expect more efficient, cost-effective, and environmentally responsible packaging solutions.

Conclusion: The Future of Packaging Solutions

As the packaging industry advances, the role of automated box-making systems becomes increasingly vital. These machines offer a robust solution for businesses looking to enhance their packaging operations through efficiency and innovation. Whether it’s through the adoption of automatic carton forming equipment or selecting the right industrial box machine supplier, companies have numerous options to explore.

Looking ahead, the future of packaging solutions lies in the continued integration of smart technologies and sustainable practices. As businesses strive to meet consumer demands and regulatory requirements, the focus will be on developing packaging solutions that are not only efficient but also environmentally responsible. By staying informed about the latest trends and innovations, companies can position themselves for success in an ever-evolving market.

Ultimately, investing in advanced packaging technology is a strategic move that can drive growth and competitiveness. With the right tools and partners, businesses can achieve significant improvements in their packaging processes, leading to enhanced operational efficiency and customer satisfaction.