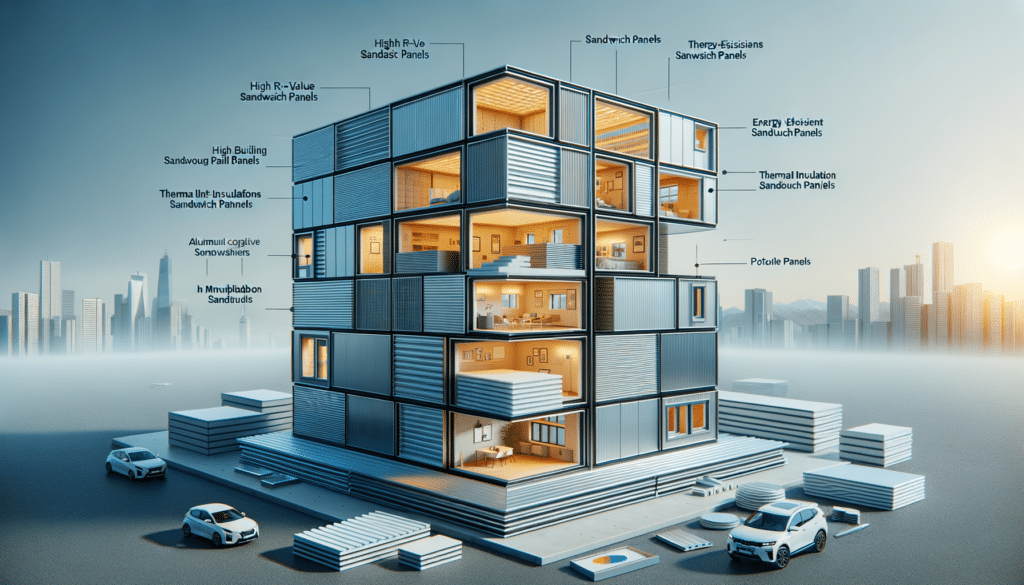

Modular Building Sandwich Panels: A Modern Approach to Construction

In the evolving world of construction, modular building sandwich panels have emerged as a game-changer. These panels are prefabricated, meaning they are manufactured off-site and then transported to the construction site for assembly. This method significantly reduces construction time, minimizes waste, and enhances quality control, making it an attractive option for builders and developers.

The core of modular building sandwich panels usually consists of a lightweight, insulating material such as polystyrene or polyurethane, sandwiched between two layers of durable material like steel or aluminum. This composition not only provides excellent thermal insulation but also contributes to the structural integrity of the building. These panels are particularly useful in modular construction, where quick assembly and disassembly are crucial.

Moreover, the use of modular building sandwich panels aligns with sustainable building practices. By reducing onsite construction activities, these panels help decrease noise pollution and lower the carbon footprint of a project. As urban areas continue to grow, the demand for efficient and sustainable building solutions like modular building sandwich panels is expected to rise.

High R-Value Sandwich Panels: Maximizing Thermal Efficiency

High R-value sandwich panels are designed to provide superior thermal insulation, which is a critical factor in energy-efficient building design. The R-value measures a material’s resistance to heat flow; the higher the R-value, the better the material insulates. These panels are constructed with a core material that has excellent insulating properties, such as expanded polystyrene (EPS), extruded polystyrene (XPS), or polyisocyanurate.

Incorporating high R-value sandwich panels into a building’s design can lead to substantial energy savings. By reducing the amount of heat that escapes in winter or enters in summer, these panels help maintain a stable indoor temperature, reducing the need for heating and cooling systems. This not only lowers energy bills but also contributes to a building’s overall sustainability.

Furthermore, high R-value panels are often used in applications where strict energy codes and standards must be met. They are ideal for cold storage facilities, energy-efficient homes, and commercial buildings aiming for green certifications. The ability of these panels to enhance a building’s thermal performance makes them a wise investment for those focused on long-term energy efficiency.

Energy-Efficient Building Panels: The Future of Sustainable Construction

As the construction industry moves towards more sustainable practices, energy-efficient building panels have become increasingly important. These panels are designed to minimize energy consumption by enhancing a building’s thermal and acoustic performance. They are often used in both residential and commercial projects to improve energy efficiency and occupant comfort.

Energy-efficient building panels come in various forms, including insulated metal panels, structural insulated panels (SIPs), and insulated concrete forms (ICFs). Each type offers unique advantages, such as improved insulation, reduced thermal bridging, and enhanced structural support. By choosing the right type of panel, builders can significantly reduce a building’s environmental impact.

In addition to their insulating properties, energy-efficient panels often incorporate other sustainable features, such as recycled materials or low-VOC finishes. These attributes contribute to healthier indoor environments and align with the growing demand for eco-friendly building solutions. As regulations around building energy efficiency become more stringent, the adoption of energy-efficient building panels is expected to increase, paving the way for a more sustainable future in construction.