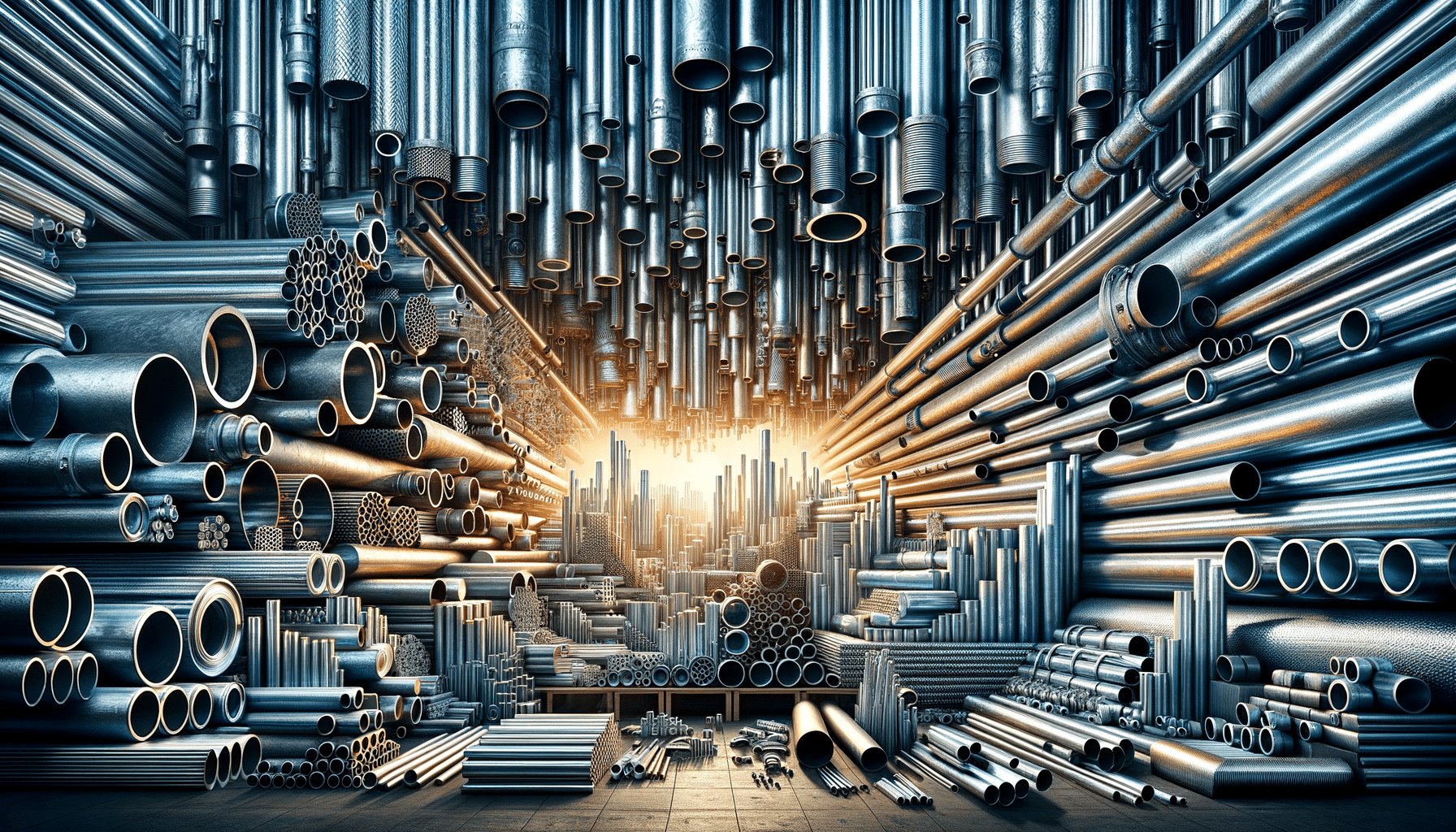

Discover durable Galvanized Steel Pipes, Tubes, and Water Pipes reliable for plumbing, construction, and industrial use.

The Basics of Galvanized Steel Pipes

Galvanized steel pipes are a staple in various industries due to their exceptional durability and resistance to corrosion. These pipes are coated with a layer of zinc, which acts as a protective barrier against rust and other environmental factors. This makes them particularly suitable for outdoor and industrial applications where exposure to moisture is common.

The process of galvanization involves immersing steel pipes in molten zinc, ensuring a uniform coating. This not only enhances the lifespan of the pipes but also provides a smooth surface that is less prone to the buildup of debris. Galvanized steel pipes are commonly used in plumbing, construction, and even in the automotive industry for exhaust systems.

Some key benefits of galvanized steel pipes include:

- Corrosion resistance: The zinc coating prevents rust, extending the life of the pipes.

- Durability: These pipes can withstand high pressure and heavy loads.

- Cost-effectiveness: They offer a balance of performance and affordability.

Despite their advantages, it’s important to note that galvanized steel pipes are not ideal for all applications. For instance, in areas with highly acidic water, the zinc coating may degrade over time. Therefore, understanding the specific requirements of your project is crucial when choosing materials.

Understanding Galvanized Steel Tubes

Galvanized steel tubes share many similarities with their pipe counterparts, yet they are distinct in their applications and characteristics. Tubes are generally used in structural applications, such as in the construction of buildings, bridges, and other infrastructure projects. Their strength and rigidity make them a reliable choice for load-bearing structures.

One of the key differences between pipes and tubes is their measurement and sizing. While pipes are measured by their inner diameter, tubes are measured by their outer diameter. This difference is crucial when precision and fit are important factors in a project.

Galvanized steel tubes are valued for their:

- Strength-to-weight ratio: They provide excellent support without adding excessive weight.

- Versatility: Available in various shapes and sizes to suit different needs.

- Resistance to environmental factors: Like pipes, tubes benefit from the protective zinc coating.

These tubes are not only used in construction but also in the manufacturing of furniture, automotive components, and even in agricultural equipment. Their adaptability to different environments and applications makes them a favored choice across industries.

The Role of Galvanized Water Pipes

Galvanized water pipes have been a popular choice for plumbing systems due to their ability to resist corrosion and ensure long-lasting performance. These pipes are particularly effective in delivering water to homes and businesses, as the zinc coating helps prevent the contamination of the water supply by rust.

However, it’s essential to be aware of potential drawbacks. Over time, the zinc coating can wear down, especially in areas with high water acidity, leading to the exposure of the underlying steel. This can result in rust and reduced water flow due to the buildup of minerals inside the pipes.

Despite these challenges, galvanized water pipes remain a practical solution for many applications, especially where budget constraints are a consideration. They offer a cost-effective alternative to more expensive materials while still providing reliable performance.

When considering galvanized water pipes, it’s important to:

- Assess the water quality to ensure compatibility with the zinc coating.

- Regularly inspect and maintain the pipes to extend their lifespan.

- Consider alternatives for areas with known issues of high water acidity.

Understanding the specific needs of your plumbing system will help in making an informed decision about the use of galvanized water pipes.

Comparing Galvanized Steel Pipes and Tubes

While galvanized steel pipes and tubes share the common advantage of corrosion resistance, their applications and characteristics are tailored to different needs. Pipes are generally used for the transportation of fluids and gases, making them a critical component in plumbing and industrial systems. Tubes, on the other hand, are more focused on structural applications due to their precision and strength.

Choosing between the two depends largely on the specific requirements of your project. Consider the following factors:

- Purpose: Determine whether the primary need is for fluid transport or structural support.

- Size and shape: Pipes are typically round, while tubes can come in various shapes.

- Pressure requirements: Pipes are designed to handle high-pressure applications, whereas tubes offer more flexibility in terms of design.

Both galvanized steel pipes and tubes offer durability and protection against environmental factors, but understanding their distinct features will guide you in selecting the right material for your needs.

Conclusion: The Versatility of Galvanized Steel Products

Galvanized steel pipes, tubes, and water pipes provide a versatile and reliable solution for a wide range of applications. Their ability to withstand harsh environments, resist corrosion, and offer durability makes them a practical choice for industries such as construction, plumbing, and manufacturing.

When selecting galvanized steel products, it’s important to assess the specific needs of your project, including environmental conditions and budget constraints. With careful consideration, these products can offer exceptional performance and longevity, ensuring the success of your endeavors.

In conclusion, galvanized steel remains a trusted material across industries, providing both performance and protection where it matters most.