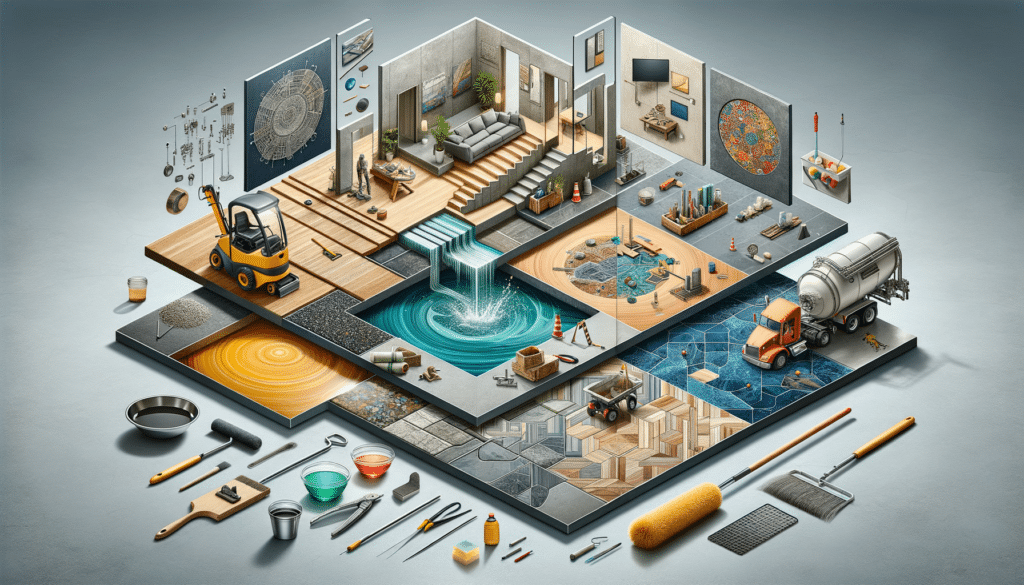

Resin Flooring Benefits

Resin flooring has emerged as a versatile and durable option for various environments, ranging from industrial spaces to residential homes. The primary benefits of resin flooring include its exceptional durability and resistance to wear and tear. This flooring type is known for its ability to withstand high levels of foot traffic and heavy machinery, making it an ideal choice for warehouses and factories. Additionally, resin floors are highly resistant to chemicals and spills, ensuring longevity even in harsh conditions. The seamless nature of resin flooring also contributes to its hygienic properties, as it prevents the accumulation of dirt and bacteria, making it easier to clean and maintain.

Another significant advantage of resin flooring is its aesthetic versatility. Available in a wide range of colors and finishes, it allows for creative designs and patterns, enhancing the visual appeal of any space. Whether aiming for a sleek, modern look or a vibrant, colorful atmosphere, resin flooring can be customized to meet diverse stylistic preferences. Furthermore, its reflective surface can enhance lighting in a room, contributing to energy efficiency by reducing the need for additional lighting fixtures.

In terms of cost-effectiveness, resin flooring offers an excellent return on investment. Its durability reduces the need for frequent replacements, and its low maintenance requirements save time and money. Overall, resin flooring provides a blend of functionality, aesthetics, and economic benefits, making it a highly regarded choice for various applications.

Epoxy Resin Floor Installation

Installing epoxy resin flooring is a meticulous process that requires careful preparation and execution to achieve optimal results. The first step in the installation process involves thoroughly cleaning and preparing the substrate. This includes removing any existing coatings, repairing cracks, and ensuring the surface is smooth and free of contaminants. Proper preparation is crucial, as it ensures the epoxy resin adheres effectively to the substrate, preventing issues such as peeling or bubbling.

Once the surface is prepared, the next step is to apply a primer coat, which acts as a bonding agent between the substrate and the epoxy resin. After the primer has cured, the epoxy resin is mixed and applied in multiple layers. Each layer must be allowed to cure before applying the next, ensuring a strong and durable finish. The final layer often includes a topcoat, which provides additional protection and enhances the floor’s appearance.

It is essential to follow the manufacturer’s instructions and guidelines throughout the installation process to ensure the longevity and performance of the epoxy resin floor. Hiring professional installers can also be beneficial, as they have the expertise and equipment necessary to execute the installation efficiently and effectively. Proper installation not only enhances the floor’s durability but also maximizes its aesthetic appeal, making epoxy resin flooring a valuable addition to any space.

Types of Resin Flooring

Resin flooring is available in several types, each with distinct characteristics and applications. The most common types include epoxy resin flooring, polyurethane resin flooring, and methyl methacrylate (MMA) resin flooring.

Epoxy resin flooring is renowned for its strength and durability, making it suitable for industrial and commercial environments. It offers excellent resistance to chemicals, abrasion, and impact, making it ideal for areas with heavy machinery and high foot traffic. Epoxy floors are also customizable, with various colors and finishes available to suit different design preferences.

Polyurethane resin flooring is known for its flexibility and resistance to thermal shock, making it a preferred choice for environments with temperature fluctuations, such as food processing facilities. It also offers good resistance to chemicals and is more UV stable than epoxy, making it suitable for outdoor applications.

Methyl methacrylate (MMA) resin flooring is valued for its rapid curing time, allowing for quick installation and minimal downtime. This type of flooring is often used in environments that require fast turnaround times, such as hospitals and retail spaces. MMA floors are also highly resistant to chemicals and temperature changes, providing a durable and versatile flooring solution.

Understanding the different types of resin flooring and their unique properties can help in selecting the most appropriate option for specific needs and environments, ensuring optimal performance and longevity.