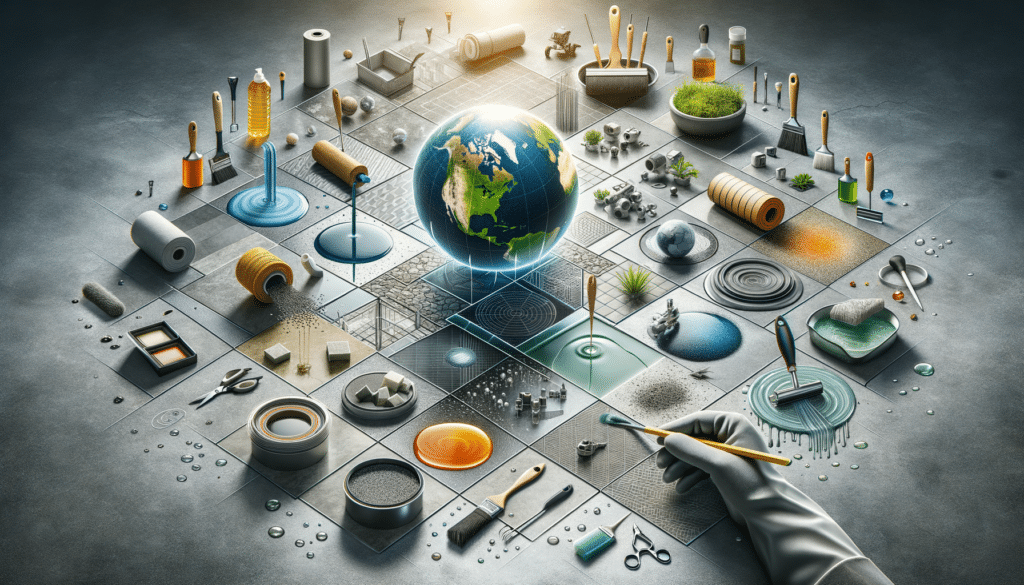

Resin Flooring Benefits

Resin flooring is an innovative solution that combines durability with aesthetic versatility, making it a popular choice for both residential and commercial spaces. One of the most significant benefits of resin flooring is its remarkable durability. Resin floors are highly resistant to wear and tear, making them ideal for high-traffic areas. They are also resistant to chemicals and spills, which is particularly beneficial in industrial settings where such exposures are common. Additionally, resin flooring provides a seamless, hygienic surface that is easy to clean and maintain, reducing the time and effort spent on upkeep.

Beyond its durability, resin flooring offers a wide range of design options. Available in various colors and finishes, resin floors can be customized to fit the aesthetic of any space. This flexibility allows homeowners and businesses to create unique, visually appealing environments that align with their brand or personal style. Moreover, resin flooring can be applied over existing floors, eliminating the need for costly and time-consuming demolition work.

In terms of safety, resin flooring is slip-resistant, which is a crucial feature in environments where safety is a top priority, such as kitchens and industrial facilities. The seamless nature of resin floors also means there are no joints or seams where dirt and bacteria can accumulate, promoting a cleaner and healthier environment. Overall, resin flooring is a cost-effective solution that offers long-term value through its durability, versatility, and ease of maintenance.

Epoxy Resin Floor Installation

Installing an epoxy resin floor involves several key steps that ensure a durable and aesthetically pleasing finish. The process begins with thorough surface preparation, which is crucial for achieving proper adhesion. This involves cleaning the existing floor to remove any dust, dirt, or grease, and repairing any cracks or imperfections. Once the surface is clean and smooth, a primer is applied to improve the bond between the substrate and the epoxy coating.

After the primer has dried, the epoxy resin is mixed and applied. This is typically done in layers, allowing each coat to cure before applying the next. The number of layers will depend on the desired thickness and the specific requirements of the space. For areas that require additional slip resistance, aggregates can be added to the epoxy mixture, providing a textured finish that enhances safety.

The final step in the installation process is the application of a topcoat, which provides additional protection against wear and UV damage, ensuring the floor maintains its appearance and functionality over time. It’s important to note that epoxy resin floors require a curing period, during which the floor should not be subjected to heavy traffic or exposure to water. This period can vary depending on the specific product used, but it typically ranges from 24 to 72 hours.

Overall, while epoxy resin floor installation requires careful preparation and attention to detail, the result is a high-performance floor that combines durability with visual appeal. By following the proper installation steps and allowing adequate curing time, property owners can enjoy the benefits of epoxy resin flooring for years to come.

Types of Resin Flooring

Resin flooring encompasses a variety of types, each offering unique characteristics suited to different applications. The most common types include epoxy, polyurethane, and acrylic resin floors, each with its own set of advantages.

Epoxy resin flooring is renowned for its strength and durability, making it an excellent choice for industrial and commercial environments. It is highly resistant to chemicals, stains, and abrasion, and provides a seamless, easy-to-clean surface. The aesthetic flexibility of epoxy flooring is also noteworthy, as it can be customized with various colors and patterns to enhance the visual appeal of any space.

Polyurethane resin flooring, on the other hand, is known for its flexibility and resistance to thermal shock, which makes it suitable for environments that experience temperature fluctuations or heavy mechanical stress. This type of flooring is often used in food processing facilities and commercial kitchens due to its ability to withstand high temperatures and its resistance to chemicals.

Acrylic resin flooring offers a quick-curing solution that is ideal for projects with tight timelines. It provides a durable and UV-resistant finish, making it suitable for both indoor and outdoor applications. Acrylic floors are often used in retail spaces and public buildings where rapid installation and minimal downtime are crucial.

In conclusion, the choice of resin flooring type depends on the specific needs and conditions of the environment in which it will be installed. By understanding the unique properties of each type, property owners can select the most appropriate resin flooring solution to meet their functional and aesthetic requirements.