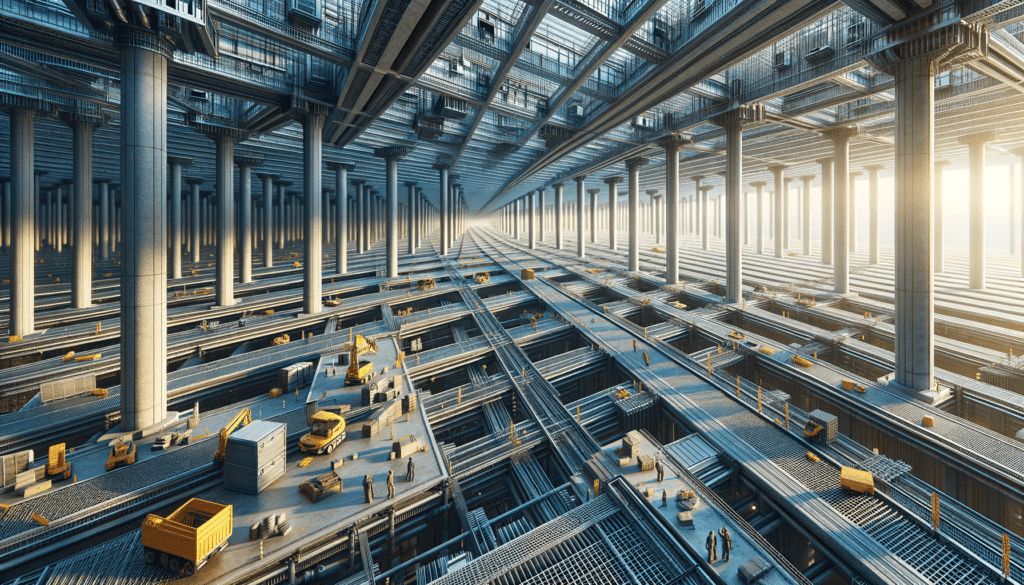

Understanding Fiberglass Grating: A Modern Marvel

Fiberglass grating is a composite material made from fiberglass reinforced plastic (FRP), known for its exceptional durability and versatility. This material has become a popular choice in construction due to its lightweight nature and resistance to corrosion. Unlike traditional materials such as steel or wood, fiberglass grating does not rust, rot, or succumb to chemical damage, making it an ideal candidate for various industrial applications. The structure of fiberglass grating involves a matrix of resin and fiberglass strands, providing strength and flexibility. Its unique composition allows it to withstand harsh environments, including exposure to chemicals, moisture, and extreme temperatures, without compromising its structural integrity.

Applications in Construction: A Versatile Solution

Fiberglass grating is utilized in numerous construction projects, ranging from industrial flooring to pedestrian walkways. Its non-slip surface enhances safety, while its lightweight nature simplifies installation and reduces labor costs. In industrial settings, fiberglass grating is often used in chemical plants, wastewater treatment facilities, and offshore platforms due to its resistance to corrosive substances. Its versatility extends to architectural projects, where it can be used for decorative facades or sunshades, offering both aesthetic appeal and functionality. The adaptability of fiberglass grating makes it a valuable asset in modern construction, catering to diverse needs and environments.

Comparing Fiberglass Grating to Traditional Materials

When compared to traditional materials like steel or aluminum, fiberglass grating offers several advantages. It is significantly lighter, reducing transportation and installation costs. Additionally, fiberglass grating does not conduct electricity, making it a safer option in environments where electrical hazards are a concern. Its resistance to corrosion and chemicals surpasses that of metal grating, ensuring longevity and minimal maintenance. While the initial cost of fiberglass grating may be higher than some traditional materials, its durability and low maintenance requirements often result in cost savings over time. These attributes make fiberglass grating a practical and economical choice for many construction projects.

Environmental Impact and Sustainability

In today’s construction industry, sustainability is a critical consideration. Fiberglass grating contributes positively to environmental goals due to its long lifespan and minimal maintenance needs. The production process of fiberglass grating involves fewer emissions compared to metal manufacturing, and its lightweight nature reduces energy consumption during transportation. Moreover, fiberglass grating is fully recyclable, aligning with sustainable construction practices. By incorporating fiberglass grating into projects, builders can enhance the environmental profile of their constructions, supporting eco-friendly initiatives and reducing the overall carbon footprint.

Future Prospects and Innovations

The future of fiberglass grating in construction looks promising, with ongoing innovations enhancing its performance and applications. Researchers are exploring new resin formulations and manufacturing techniques to increase strength and reduce costs further. Additionally, advancements in design are expanding the aesthetic possibilities of fiberglass grating, making it a more attractive option for architects and designers. As the demand for sustainable and durable construction materials grows, fiberglass grating is poised to play a significant role in shaping the future of the industry. Its ability to adapt to various needs and environments ensures its continued relevance and popularity in construction.