Explore how powered roller conveyors streamline workflow and reduce manual effort in operations.

Introduction to Powered Roller Conveyors

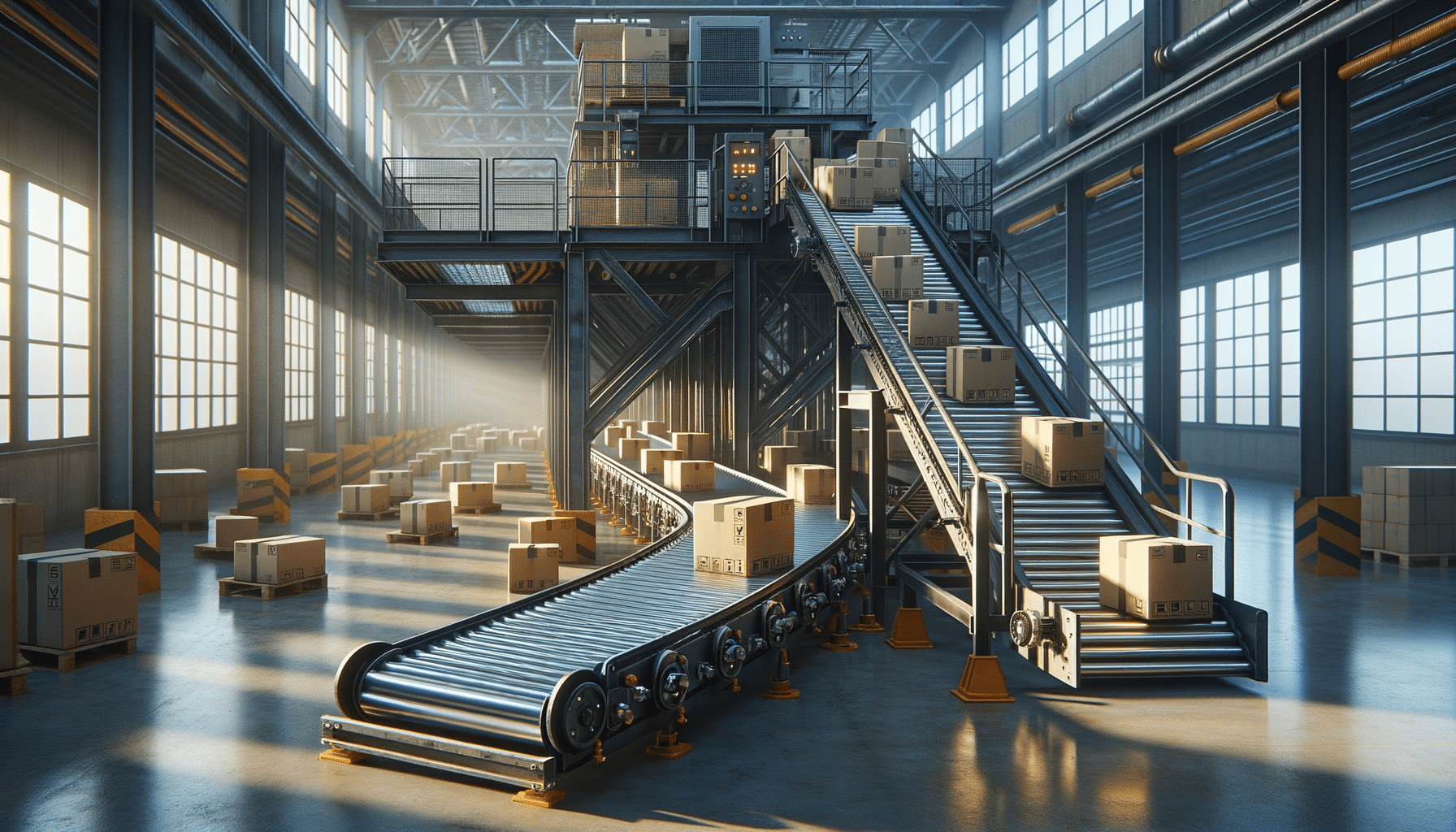

Powered roller conveyors are an integral part of modern industrial operations, providing an efficient solution for moving goods and materials across production or warehouse floors. These systems utilize motor-driven rollers to facilitate the smooth and consistent movement of various load sizes, significantly reducing the need for manual handling. This has made powered roller conveyors a staple in industries such as manufacturing, packaging, and distribution, where workflow optimization and reduced labor costs are critical.

In this article, we will delve into the various aspects of powered roller conveyors, covering their industrial applications, the efficiency they bring to material handling, the different designs and configurations available, maintenance tips, and guidance on selecting the right system for your facility. By understanding these elements, businesses can make informed decisions to enhance their operational efficiency.

Industrial Applications of Powered Roller Conveyor Systems

Powered roller conveyor systems are utilized in a diverse range of industrial applications due to their versatility and efficiency. These systems are particularly prevalent in sectors that require the rapid and reliable transport of goods, such as automotive manufacturing, food processing, and e-commerce fulfillment centers.

For instance, in the automotive industry, powered roller conveyors streamline the assembly line process by moving parts and components swiftly between workstations. This not only accelerates production but also ensures precision and consistency in assembly tasks. Similarly, in food processing, these conveyors help maintain hygiene and speed by transporting products through various stages of production and packaging seamlessly.

Other notable applications include their use in distribution centers where they facilitate the sorting and dispatching of packages, and in airports for baggage handling. The adaptability of powered roller conveyors to handle different load sizes and types makes them indispensable in these environments, contributing to enhanced operational efficiency and reduced handling times.

How Powered Roller Conveyors Improve Material Handling Efficiency

The efficiency of material handling processes is significantly enhanced with the implementation of powered roller conveyors. These systems offer a streamlined method of moving goods, which translates into several operational benefits.

Firstly, powered roller conveyors reduce the need for manual labor, thereby minimizing the risk of workplace injuries and associated costs. Automated movement of goods ensures consistency and accuracy, which is particularly important in environments where precision is paramount. Additionally, these systems can be integrated with other automated solutions such as sorting and scanning equipment, further enhancing their utility.

Furthermore, powered roller conveyors contribute to a reduction in operational bottlenecks. By maintaining a continuous flow of materials, these conveyors help prevent delays and inefficiencies that can occur with manual handling. The ability to adjust speed and direction also allows businesses to customize their material handling processes according to specific operational needs, ensuring optimal performance and productivity.

Types of Powered Roller Conveyor Designs and Configurations

When it comes to powered roller conveyors, there is a wide array of designs and configurations available to suit different industrial needs. Understanding the variety can aid businesses in choosing the most suitable system for their specific applications.

Common types include straight conveyors for linear transportation and curved conveyors for navigating tight spaces or corners. Accumulation conveyors are designed to temporarily hold items until they are ready to be processed further, making them ideal for buffering in production lines. Zero-pressure conveyors, on the other hand, eliminate contact between products, reducing the risk of damage.

Each design comes with its own set of features and benefits, allowing for customization based on factors like product type, weight, and required speed. The choice of materials, such as stainless steel for food-grade applications or heavy-duty steel for industrial use, further tailors these systems to meet specific environmental and operational demands.

Maintenance Tips for Long-Lasting Powered Roller Conveyors

To ensure the longevity and reliability of powered roller conveyors, regular maintenance is crucial. Proper upkeep not only prevents unexpected breakdowns but also optimizes the performance of the system.

Key maintenance tips include regular inspection of rollers and motors to detect wear and tear early. Lubrication of moving parts is essential to maintain smooth operation and prevent friction-related damage. Additionally, keeping the conveyor clean from debris and dust helps avoid blockages and ensures efficient operation.

It’s also important to routinely check the alignment and tension of belts and chains, as misalignment can lead to increased wear and energy consumption. Implementing a scheduled maintenance plan ensures that potential issues are addressed proactively, minimizing downtime and extending the service life of the conveyor system.

Choosing the Right Powered Roller Conveyor for Your Facility

Selecting the appropriate powered roller conveyor for your facility involves considering several factors to ensure the system meets your operational needs effectively.

Begin by assessing the specific requirements of your application, such as load capacity, speed, and environmental conditions. Understanding these parameters will guide you in choosing the right design and configuration. Additionally, consider the layout of your facility and how the conveyor will integrate with existing systems and processes.

Budget considerations are also important, but it’s crucial to balance cost with quality and durability. Investing in a high-quality conveyor can lead to long-term savings through reduced maintenance and operational efficiency. Consulting with manufacturers or industry experts can provide valuable insights and recommendations tailored to your unique needs.

By carefully evaluating these aspects, businesses can select a powered roller conveyor that enhances their material handling capabilities, leading to improved productivity and cost-effectiveness.