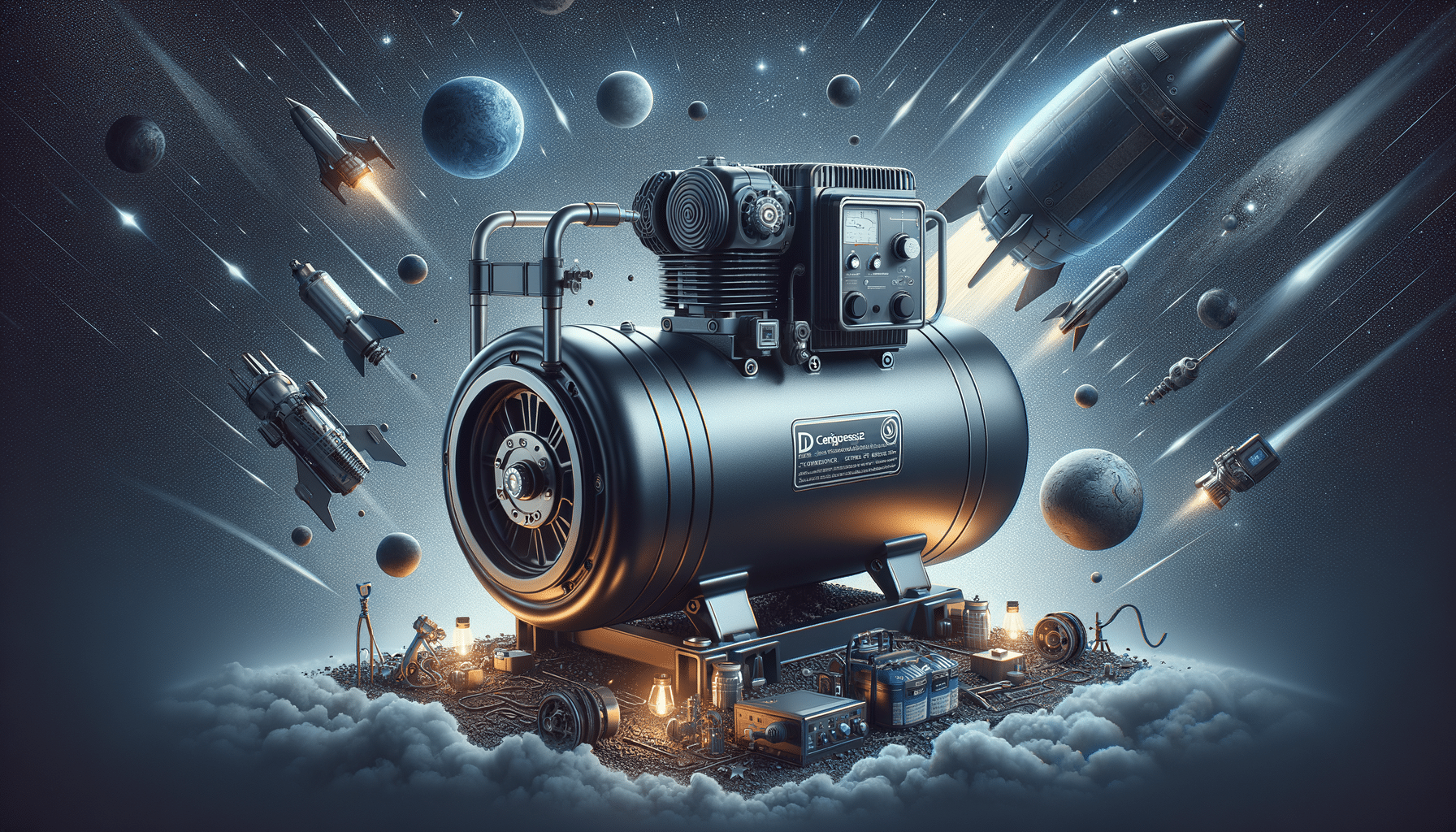

Power up with piston air compressors — durable, commercial-grade performance for every heavy-duty job.

Introduction to Piston Air Compressors

Piston air compressors, also known as reciprocating compressors, play a crucial role in various industrial and commercial settings. These machines are designed to convert power into potential energy stored in pressurized air. By using pistons driven by a crankshaft, they compress air and store it in a tank, ready for use in powering tools and machinery. Their robust design makes them suitable for a wide range of applications, from automotive workshops to large-scale manufacturing plants.

One of the key benefits of piston air compressors is their ability to deliver high-pressure air consistently. This makes them an ideal choice for environments where reliable air supply is critical. Additionally, their relatively simple design means they are easier to maintain compared to more complex systems. This combination of performance and maintainability ensures that piston air compressors remain a popular choice for businesses looking to optimize their operations.

Understanding Commercial Air Compressors

Commercial air compressors are designed to meet the demanding needs of businesses that require a reliable source of compressed air. These units are typically larger and more powerful than those used in residential settings, providing the capacity needed to support multiple tools and applications simultaneously. They are essential in industries such as construction, automotive repair, and manufacturing, where air-powered tools are frequently used.

When selecting a commercial air compressor, it’s important to consider factors such as the required air pressure, flow rate, and duty cycle. These parameters will determine the compressor’s suitability for a particular application. Additionally, commercial compressors often come with advanced features such as variable speed drives and integrated control systems, which enhance efficiency and reduce energy consumption.

Comparing Piston and Commercial Air Compressors

While piston air compressors are a type of commercial air compressor, it’s important to understand the distinctions between different models and their applications. Piston compressors are known for their durability and ability to produce high-pressure air, making them suitable for heavy-duty tasks. However, they may not be the most efficient option for applications requiring continuous air supply, as they are typically designed for intermittent use.

In contrast, rotary screw compressors, another type of commercial compressor, are designed for continuous operation and are often used in environments where a constant air supply is necessary. These compressors use a rotary mechanism to compress air, resulting in a smoother and quieter operation. When choosing between piston and other commercial compressors, businesses must assess their specific needs and operational requirements.

Maintenance and Care for Air Compressors

Proper maintenance is essential to ensure the longevity and efficiency of any air compressor. For piston air compressors, regular maintenance tasks include checking and changing the oil, inspecting and replacing air filters, and ensuring that all components are free from wear and damage. Additionally, it’s important to regularly drain the tank to prevent moisture buildup, which can lead to corrosion and other issues.

Commercial air compressors, given their larger size and complexity, may require more comprehensive maintenance routines. This can include monitoring the condition of belts and hoses, checking the electrical connections, and ensuring that the cooling system is functioning correctly. By adhering to a regular maintenance schedule, businesses can minimize downtime and extend the lifespan of their equipment.

Choosing the Right Compressor for Your Needs

When selecting an air compressor, it’s important to consider the specific requirements of your application. Factors such as the type of tools being used, the required air pressure and flow rate, and the operational environment all play a role in determining the most suitable compressor. For businesses that require high-pressure air for heavy-duty tasks, piston air compressors are often a reliable choice.

However, for applications that demand a continuous air supply, rotary screw compressors may be more appropriate. It’s also important to consider the total cost of ownership, which includes not only the initial purchase price but also the costs associated with maintenance, energy consumption, and potential downtime. By carefully evaluating these factors, businesses can make informed decisions and select a compressor that meets their needs both now and in the future.