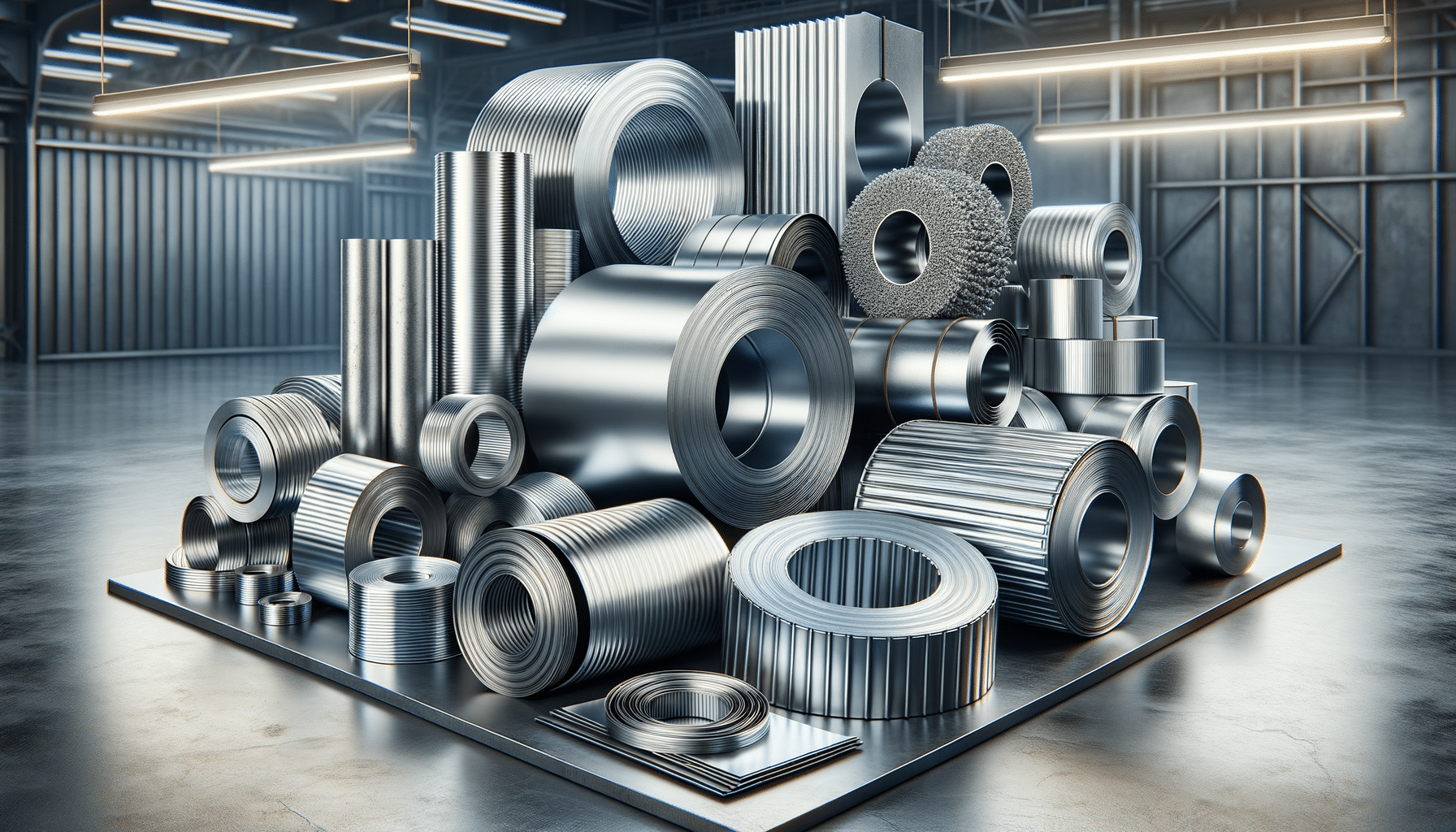

Explore Electro Galvanized Sheets, Steel Coils, and Galvanized Steel for Durable Industrial and Commercial Use.

Introduction to Galvanized Steel Products

In the world of industrial and commercial applications, materials that offer both durability and resistance to environmental factors are crucial. Among these, electro galvanized sheets, galvanized steel sheets, and galvanized steel coils stand out for their exceptional properties. These materials are indispensable in sectors such as construction, automotive, and manufacturing. Their ability to resist corrosion while maintaining structural integrity makes them a preferred choice for a wide range of applications.

Galvanization involves applying a protective zinc coating to steel or iron to prevent rusting. This process not only enhances the longevity of the metal but also improves its aesthetic appeal. The versatility of galvanized steel products allows them to be used in both indoor and outdoor settings, providing a reliable solution for projects requiring long-term durability and minimal maintenance.

Understanding Electro Galvanized Sheets

Electro galvanized sheets are a type of galvanized steel where a layer of zinc is applied through an electrochemical process. This method results in a smooth, even coating that offers excellent corrosion resistance. Electro galvanized sheets are particularly favored in applications where a high-quality surface finish is required, such as in automotive body panels and household appliances.

One of the advantages of electro galvanization is its ability to provide a uniform coating thickness, which is crucial for parts that require precision. Additionally, the process allows for better adhesion of paints and coatings, making electro galvanized sheets ideal for decorative purposes. The combination of these properties ensures that electro galvanized sheets maintain their appearance and functionality over time, even in challenging environments.

- Uniform coating thickness

- Enhanced paint adhesion

- High-quality surface finish

The Versatility of Galvanized Steel Sheets

Galvanized steel sheets are produced by immersing steel in molten zinc, a process known as hot-dip galvanization. This technique creates a robust bond between the zinc and steel, resulting in a product that is highly resistant to corrosion. Galvanized steel sheets are widely used in construction, particularly for roofing, siding, and structural components.

The protective zinc coating not only prevents rust but also provides an additional layer of protection against physical damage. This makes galvanized steel sheets an excellent choice for applications exposed to harsh weather conditions. Moreover, their cost-effectiveness and ease of fabrication further enhance their appeal in the construction industry.

- Durable zinc coating

- Cost-effective

- Suitable for harsh environments

Exploring Galvanized Steel Coils

Galvanized steel coils are another form of galvanized steel that offers flexibility and ease of use. These coils are often used in the manufacturing of products that require bending, cutting, or shaping. The continuous zinc coating on these coils ensures that the steel remains protected throughout the manufacturing process.

Galvanized steel coils are essential in the production of various consumer goods, including air conditioning ducts, furniture, and electrical appliances. Their adaptability and protective qualities make them a valuable resource in industries that demand both performance and longevity. The ability to process these coils into different shapes and sizes without compromising their protective properties is a testament to their versatility.

- Flexible and easy to use

- Continuous zinc coating

- Suitable for diverse applications

Conclusion: The Importance of Galvanized Steel Products

In summary, electro galvanized sheets, galvanized steel sheets, and galvanized steel coils offer a range of benefits that make them indispensable in various industrial and commercial applications. Their corrosion resistance, durability, and adaptability ensure that they meet the demands of different environments and uses. Whether for construction, automotive, or consumer goods manufacturing, these materials provide a reliable solution that combines functionality with aesthetic appeal.

The protective zinc coating not only enhances the life span of these steel products but also reduces maintenance costs, making them a cost-effective choice for businesses and industries. As the demand for sustainable and durable materials continues to grow, galvanized steel products remain at the forefront, offering a balance of quality, performance, and value.