Introduction to Pallet Jacks and Their Importance

Pallet jacks, whether manual or electric, are indispensable tools in warehouses and on worksites. These devices simplify the process of moving heavy loads, enhancing efficiency and reducing the risk of injury. As businesses strive to optimize their operations, the choice between manual and electric pallet jacks becomes pivotal. Manual jacks are cost-effective and require no power source, making them suitable for smaller tasks. In contrast, electric pallet jacks offer enhanced power and ease of use, ideal for larger operations requiring frequent movement of heavy goods. The decision between these options should align with the specific needs of the work environment.

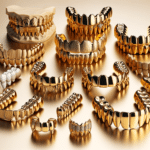

Manual vs. Electric Pallet Jacks: A Comparative Overview

Manual pallet jacks are the traditional choice for many businesses due to their simplicity and low maintenance. These jacks are operated by hand, relying on physical strength to lift and move pallets. They are highly durable and can be a cost-effective solution for businesses with limited budgets or smaller scale operations. On the other hand, electric pallet jacks provide a more advanced solution, equipped with motors that handle the lifting and moving of heavy loads with minimal effort from the operator. This can significantly reduce fatigue and increase productivity, especially in larger warehouses where frequent and heavy lifting is required. The choice between manual and electric often depends on the scale of operation, budget, and specific needs of the business.

Pallet Truck Access with Flexible Terms

Accessing pallet trucks with flexible terms is increasingly important for businesses looking to manage costs effectively. Rent-to-own options provide a viable solution, allowing businesses to use the equipment without a large initial investment. This flexibility is crucial for startups or businesses with fluctuating demand, as it provides the opportunity to scale operations without the financial burden of purchasing equipment outright. Flexible rental terms can include options such as monthly payments, the ability to upgrade equipment, and maintenance services included in the rental agreement. This approach not only aids in financial planning but also ensures that businesses have access to the latest technology without the commitment of ownership.

Equipment Solutions for Warehouse Tasks

Warehouses require a variety of equipment solutions to handle different tasks efficiently. Beyond pallet jacks, other essential equipment includes forklifts, conveyor belts, and automated storage systems. Each of these plays a vital role in ensuring smooth operations. Forklifts are crucial for lifting heavier loads that exceed the capacity of pallet jacks, while conveyor belts streamline the movement of goods across the warehouse with minimal human intervention. Automated storage systems enhance inventory management by optimizing space and improving retrieval times. By integrating these solutions, warehouses can significantly increase their operational efficiency and reduce the likelihood of errors or accidents.

Conclusion: Matching Equipment with Business Needs

In conclusion, selecting the right pallet jack and warehouse equipment is essential for optimizing operations and ensuring safety. Whether opting for manual or electric pallet jacks, businesses must consider their specific needs, budget, and the scale of their operations. Rent-to-own options provide flexibility and financial ease, allowing businesses to adapt to changing demands without significant upfront costs. By investing in the right equipment solutions, businesses can enhance productivity, reduce operational costs, and maintain a competitive edge in the market.