Introduction to Industrial Equipment

Industrial equipment plays a vital role in various sectors, from construction to manufacturing, by enhancing productivity and efficiency. These machines and tools are specifically designed to handle heavy-duty tasks that are beyond the capacity of manual labor. Understanding the different types of industrial equipment can help businesses make informed decisions about their operational needs. Whether it’s for packaging, material handling, or facility support, the right equipment can significantly impact a company’s bottom line.

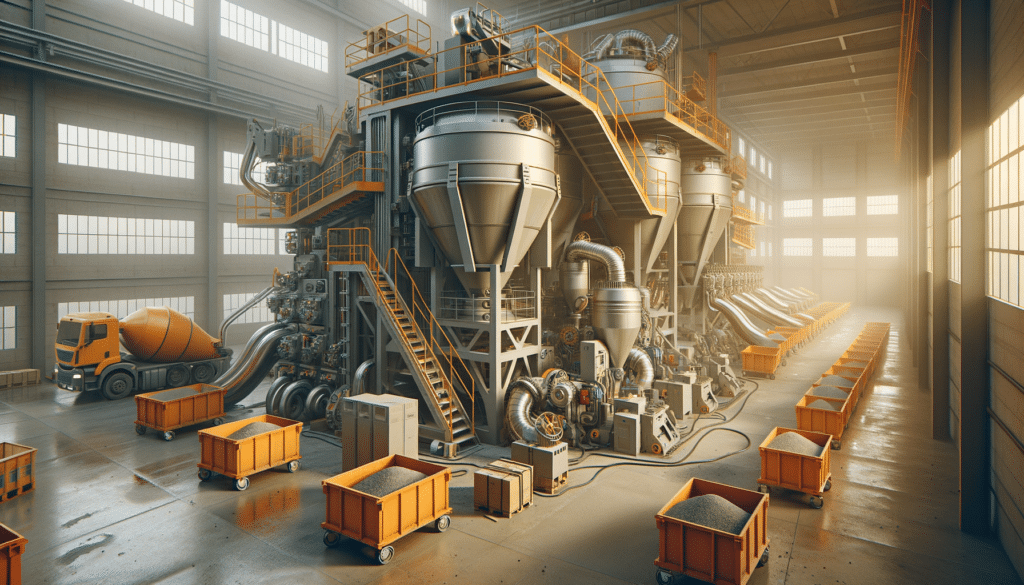

Understanding Sludge Mixer Equipment

Sludge mixer equipment is crucial in industries dealing with waste management and water treatment. These machines are designed to mix sludge with other materials to improve the treatment process. The primary function of sludge mixers is to ensure a homogeneous mixture, which is essential for effective treatment and disposal. They come in various designs, including paddle, ribbon, and vertical mixers, each suited to different types of sludge and treatment requirements.

Choosing the right sludge mixer involves considering factors such as the type of sludge, the volume to be processed, and the specific treatment goals. For instance, paddle mixers are often used for thick, viscous sludge, while ribbon mixers are suitable for lighter, more fluid materials. The efficiency of a sludge mixer can directly affect the overall effectiveness of the waste treatment process, highlighting the importance of selecting the appropriate equipment.

Exploring Box Forming Machines

Box forming machines are integral to the packaging industry, providing a streamlined solution for creating boxes of various sizes and shapes. These machines automate the process of folding and gluing cardboard to form sturdy boxes, which are then used for packaging products. The automation of box forming not only speeds up production but also ensures consistency and quality in the packaging process.

There are different types of box forming machines, including manual, semi-automatic, and fully automatic models. The choice of machine depends on the production scale and specific packaging requirements. Fully automatic machines are ideal for large-scale operations, offering high-speed production and minimal human intervention. On the other hand, semi-automatic machines provide more flexibility and are suitable for businesses with varying packaging needs.

Industrial Equipment in Construction

In the construction industry, industrial equipment is indispensable for executing large-scale projects efficiently and safely. From cranes and bulldozers to concrete mixers and excavators, each piece of equipment serves a specific purpose. These machines not only enhance productivity but also improve safety by reducing the need for manual labor in hazardous conditions.

One of the key considerations in selecting construction equipment is its versatility and adaptability to different tasks. For example, excavators can be equipped with various attachments to perform functions such as digging, lifting, and demolition. Similarly, cranes come in different types, such as tower cranes for high-rise construction and mobile cranes for more flexible operations. Understanding the capabilities and limitations of each machine is crucial for optimizing construction processes.

Conclusion: The Importance of Choosing the Right Equipment

In conclusion, the selection of industrial equipment is a critical decision that can influence the efficiency and success of operations across various industries. Whether it is sludge mixer equipment for waste management, box forming machines for packaging, or construction machinery, each type of equipment has its unique features and benefits. By understanding the specific needs of their operations and the capabilities of available equipment, businesses can enhance productivity, ensure safety, and achieve their operational goals more effectively.

Investing in the right equipment not only supports current operational demands but also positions businesses for future growth and adaptability in an ever-evolving industrial landscape.