Lathe Machines: Features, Types & What to Know Before You Buy

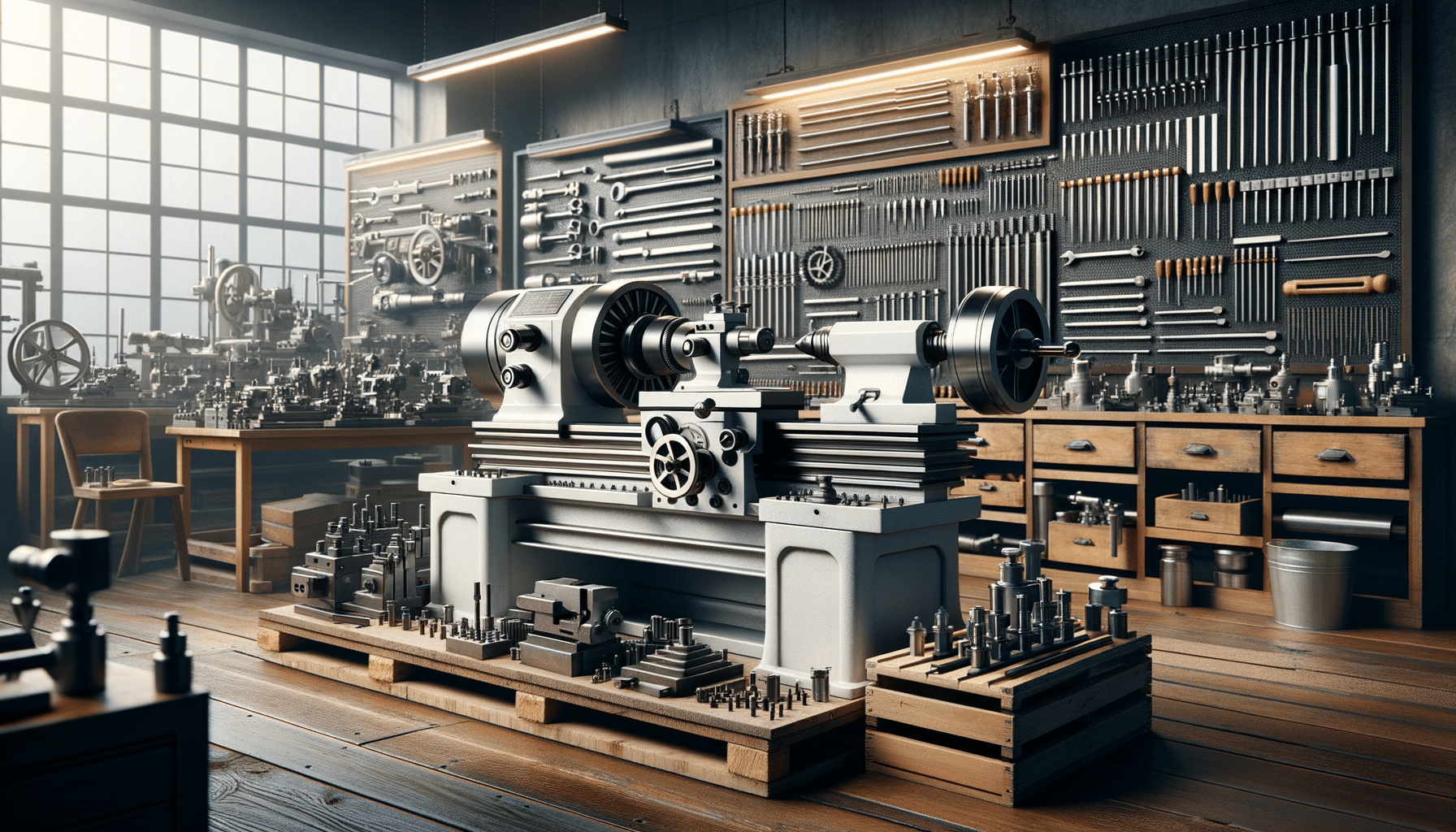

Introduction to Lathe Machines

Lathe machines have been a cornerstone in the field of manufacturing and crafting, offering unparalleled versatility in shaping, cutting, and drilling materials. Whether you’re a hobbyist or a professional, understanding the different types of lathe machines can significantly enhance your projects. This article explores various lathe machines available for sale, comparing metal and wood lathes, and delving into the distinct types of lathe machines to help you make informed decisions.

Lathe Machines for Sale: What to Consider

When considering lathe machines for sale, it’s essential to evaluate your specific needs and the materials you plan to work with. Lathe machines come in various forms, each designed for particular tasks. Here are some factors to consider:

- Size and Capacity: Determine the size of the workpieces you plan to handle. Larger lathes can accommodate bigger projects but may require more space.

- Manual vs. CNC: Decide whether a manual lathe or a CNC (Computer Numerical Control) lathe is more suitable for your precision needs.

- Budget: Prices can vary significantly, so it’s crucial to set a budget that aligns with your requirements.

By assessing these factors, you can narrow down your options and find a lathe machine that fits your workshop and project needs.

Metal Lathe vs. Wood Lathe: Key Differences

While both metal and wood lathes serve similar functions, they are tailored for different materials and applications. Understanding their differences can guide you in choosing the right tool:

- Construction: Metal lathes are generally more robust, designed to handle the stress of cutting metals. Wood lathes are lighter and often include features for handling softer materials.

- Speed and Precision: Metal lathes offer higher precision and often come with variable speed controls, essential for metalworking. Wood lathes prioritize flexibility and ease of use for shaping wood.

- Tooling: The tools used in metal lathes are typically more rigid and durable, whereas wood lathes use sharper, more varied tools for different wood types.

These differences highlight the importance of choosing a lathe based on the materials you plan to work with, ensuring efficiency and quality in your projects.

Types of Lathe Machines

Lathe machines come in various types, each suited for specific tasks and materials. Understanding these types can help you choose the right machine for your needs:

- Engine Lathe: Known for its versatility, the engine lathe is used for general-purpose tasks and can handle a wide range of materials.

- Turret Lathe: Ideal for repetitive production, turret lathes allow for quick tool changes and are excellent for mass production.

- CNC Lathe: Offering high precision and automation, CNC lathes are perfect for complex and detailed work, often used in industrial settings.

- Bench Lathe: Smaller and more compact, bench lathes are suitable for hobbyists and small workshops.

By understanding the capabilities of each type, you can select a lathe machine that aligns with your project goals and operational needs.

Conclusion: Choosing the Right Lathe Machine

In summary, selecting the right lathe machine involves understanding your specific needs, whether you’re working with metal or wood, and considering the machine’s capabilities and your budget. From metal lathes that offer precision and durability to wood lathes that provide flexibility and ease of use, the choice depends on your project requirements. By exploring the types and features of lathe machines for sale, you can make an informed decision that enhances your crafting or manufacturing processes.